Advantages

Ø Simple and user-friendly

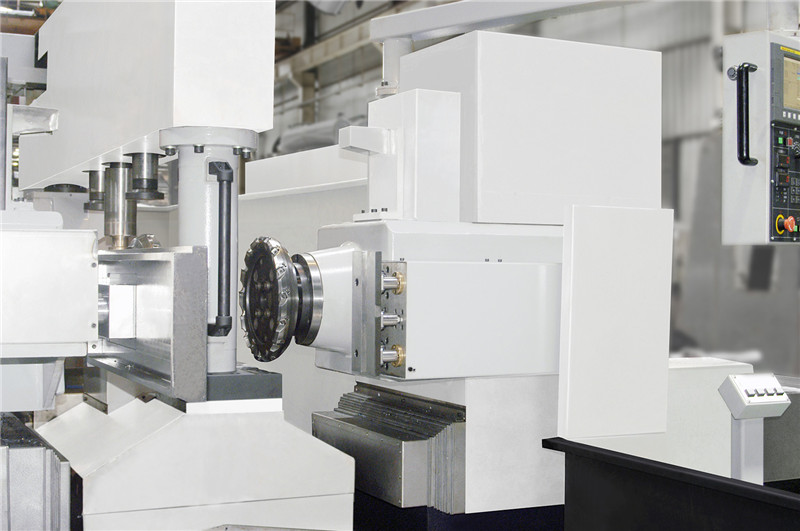

Ø The whole machine is assembled in one piece

Ø Moveable hydraulic device, flexible for crane travelling

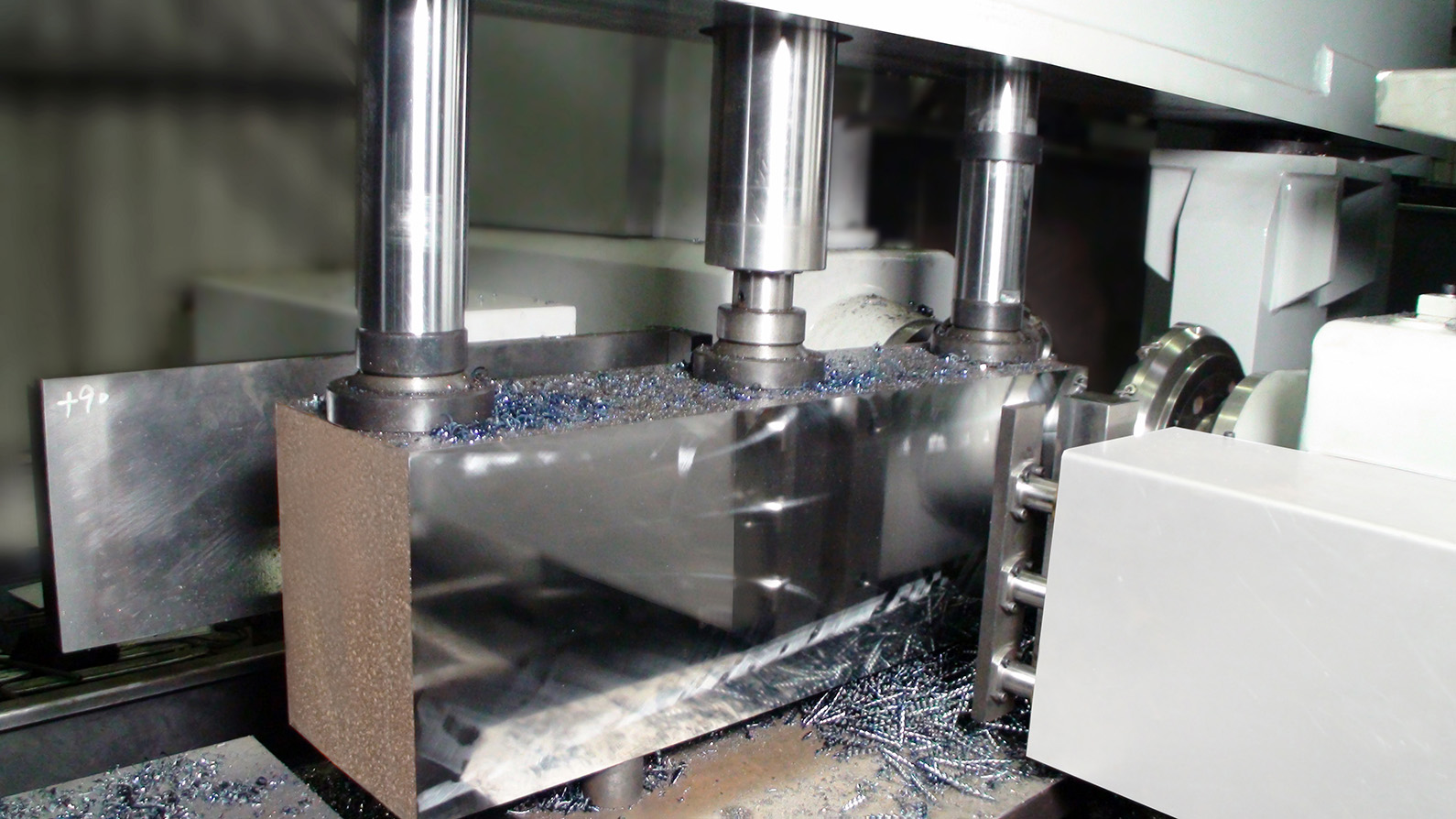

Ø The roughness can reach 0.59μm

Ø High-efficiency & cost-effective

Specifications

| Model | Unit | DPM1510 | DPM1810 | |

| Travel | X axis travel | mm | 1910 | 2200 |

| Y axis travel | mm | 455 | 455 | |

| Z axis travel | mm | 455 | 455 | |

| Distance between two spindle noses | mm | 270-1180 | 270-1180 | |

| Spindle center to worktable top | mm | 190 | 190 | |

| Max. machining material (L x W) | mm | 1500 x 1000 (2 surface) | 1800 x 1000 (2 surface) | |

| Max. cutting thickness | mm | 290 | 290 | |

| Min. machining material (L x W x H) | mm | 150 x 150 x 20 | 150 x 150 x 20 | |

| Spindle | Spindle bore taper | - | Ø 47.625 | Ø 47.625 |

| Spindle speed | rpm | 70-1000 | 70-1000 | |

| Worktable | Max. worktable loading capacity | ton | 2 | 3.5 |

| Worktable dimension | mm | 600 x 600 | 600 x 600 | |

| Minimum indexing angle | - | 90° | 90° | |

| Power | Spindle motor | kW | 15/18.5 (30min) | 15/18.5 (30min) |

| X axis servo motor | N.n | 27 | 27 | |

| Y axis servo motor | N.n | 20 | 20 | |

| Z axis servo motor | N.n | 20 | 20 | |

| Total power requirement | kW | 50 | 50 | |

| Rapid traverse rate (X、Y、Z axis) | m/min | 10 | 10 | |

| Max. diameter of cutter | - | Ø 305 (Ø 315 Optional) | Ø 305 (Ø 315 Optional) | |

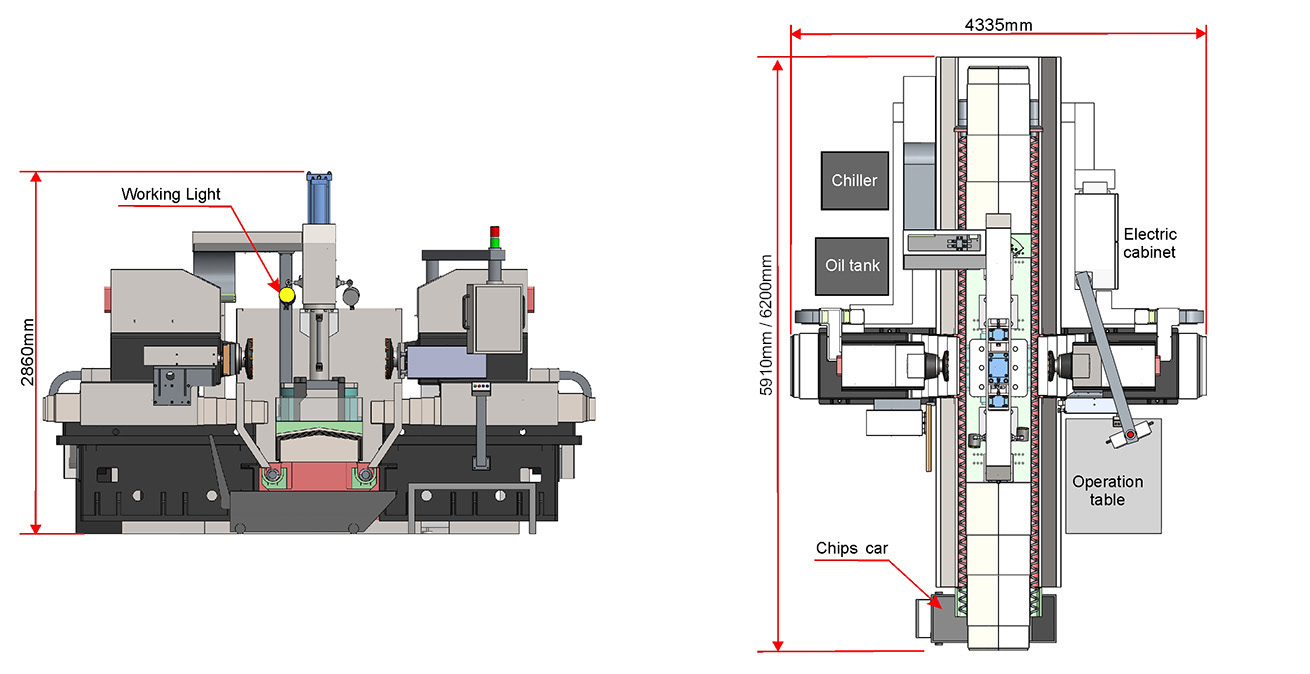

| Size & Weight | Floor space require (L x W x H) | mm | 5910 x 4335 x 2860 | 6200 x 4335 x 2860 |

| Machine weight | ton | 20 | 21 | |

| CNC system | - | - | FANUC 0i-MF | FANUC 0i-MF |

Design & specifications are subject to change without prior notice!

Design & specifications are subject to change without prior notice!Accessories

| Standard accessories | DPM1510 | DPM1810 |

| FANUC 0i-MF system |  |  |

| Manual handle feed unit |  |  |

| Air cooler for electric cabinet |  |  |

| Screw type chip conveyor (Chiller, only for DPM1510/DPM1810) |  |  |

| Pneumatic system |  |  |

| Lubricating system |  |  |

| Full guard |  |  |

| Service tools and tool box |  |  |

| Leveling screws and leveling wedges |  |  |

| Cycle indicator lamp |  |  |

| L & R Cutters |  |  |

Design & specifications are subject to change without prior notice!

Design & specifications are subject to change without prior notice!Application Case