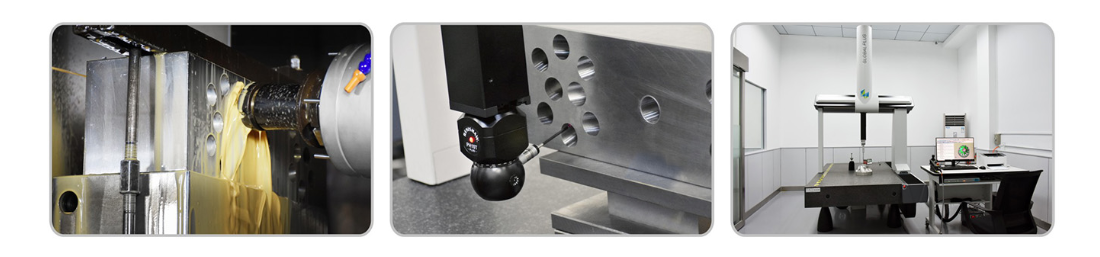

Advantages

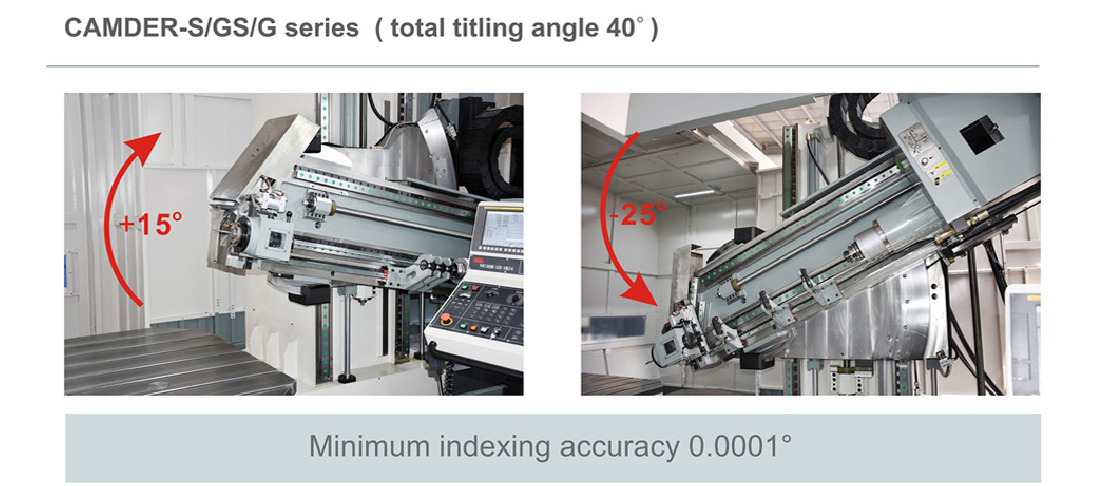

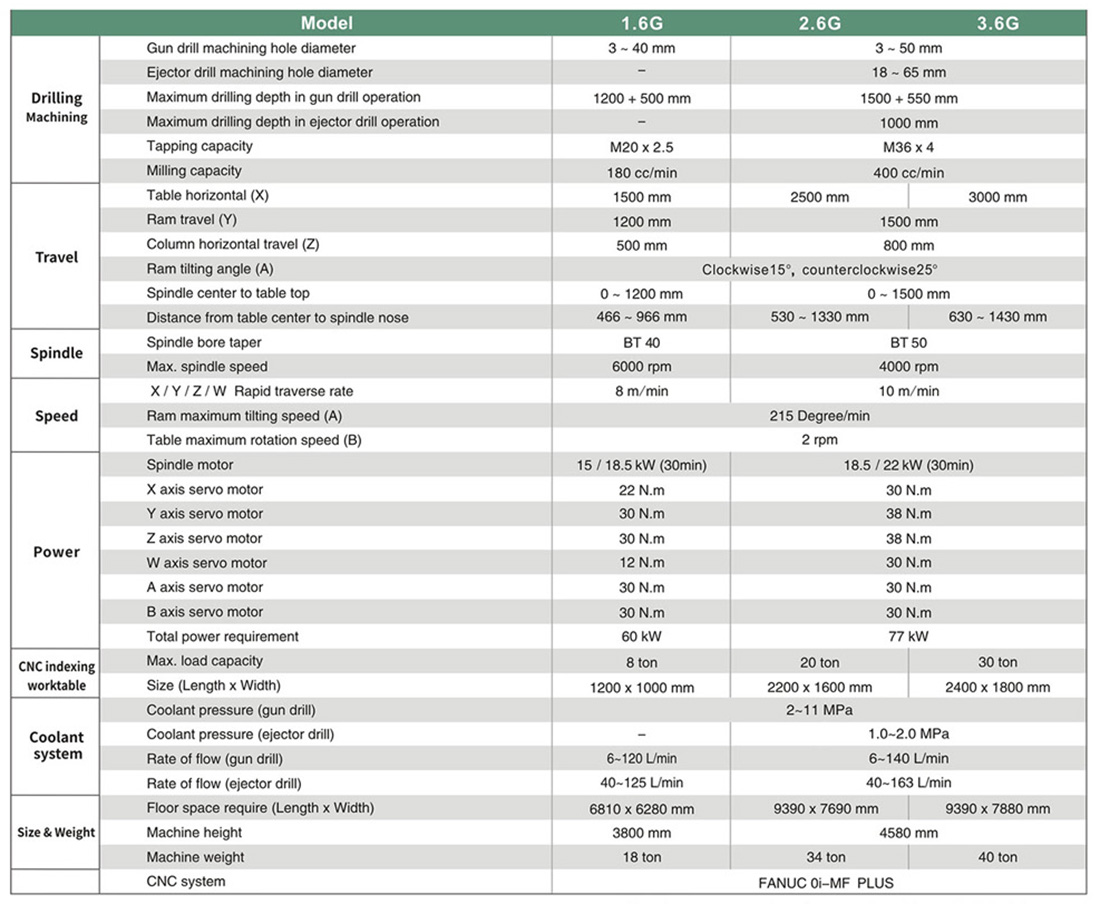

Specifications

Design & specifications are subject to change without prior notice!

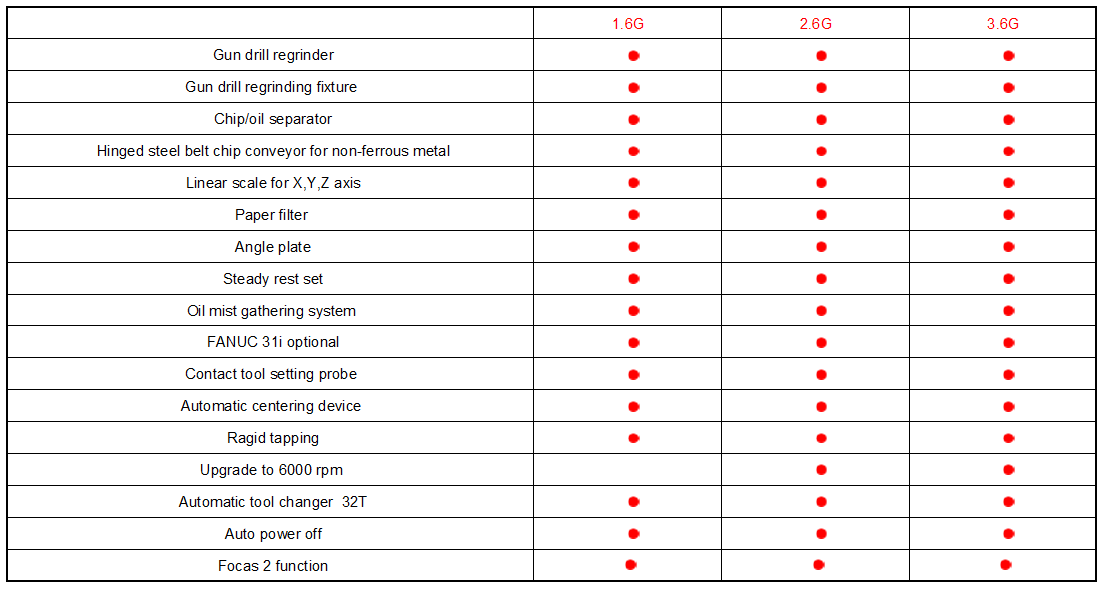

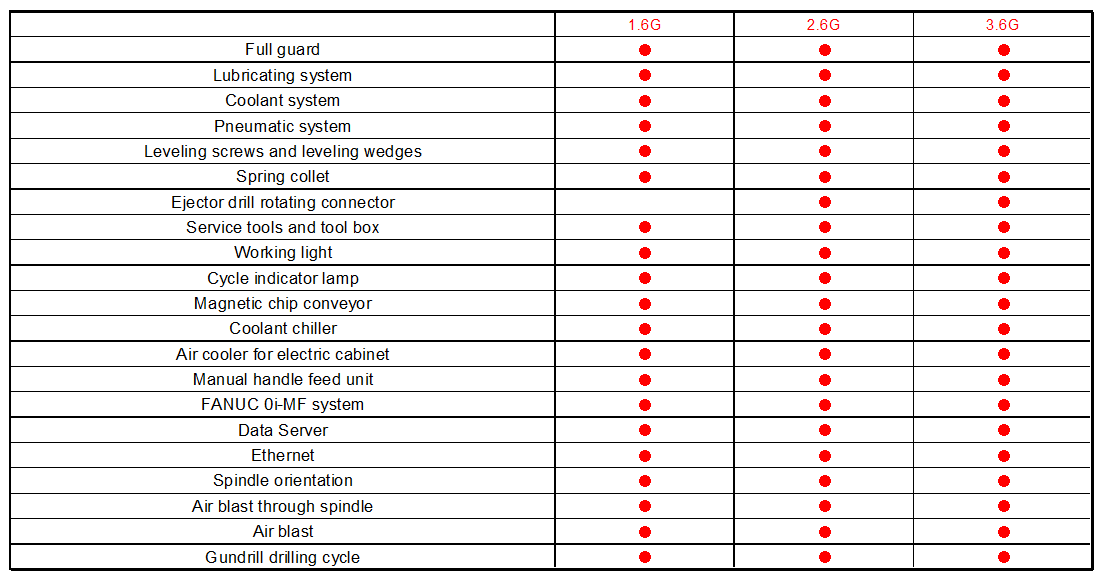

Design & specifications are subject to change without prior notice!Accessories

Design & specifications are subject to change without prior notice!

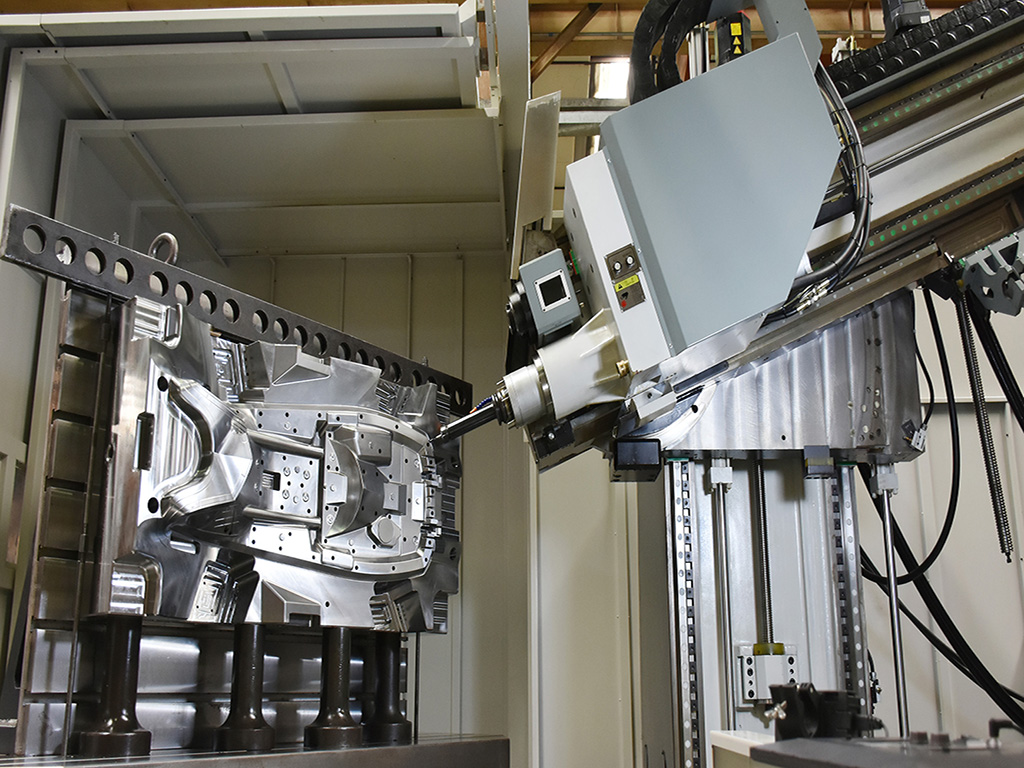

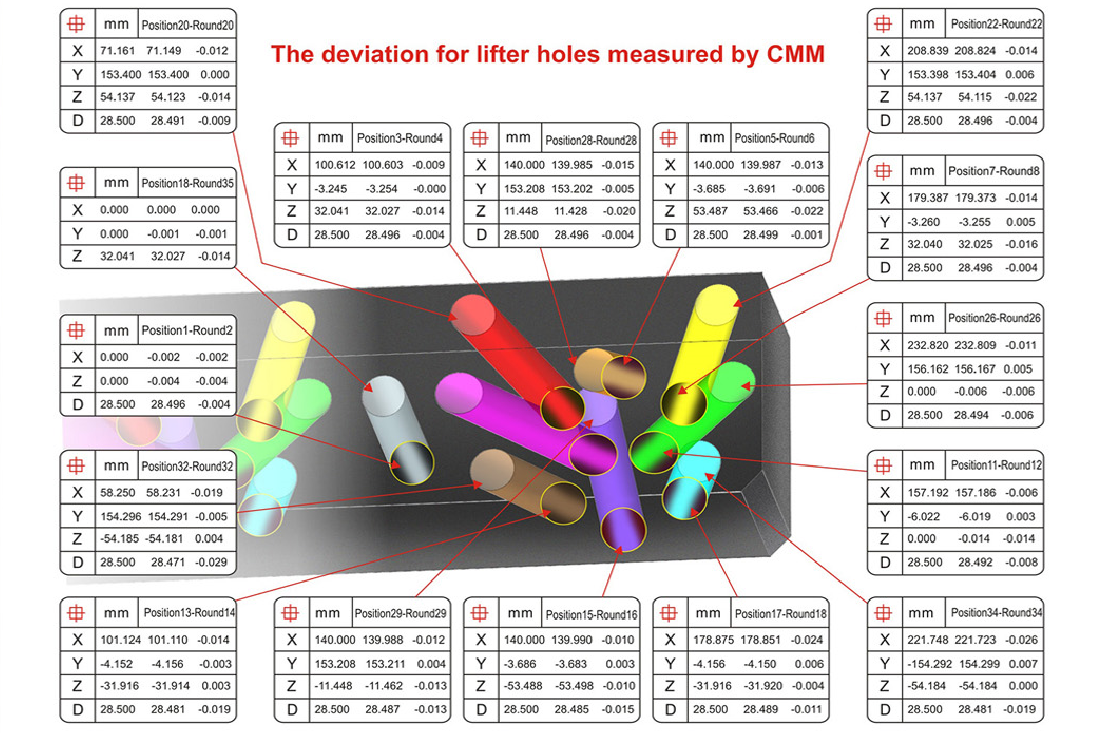

Design & specifications are subject to change without prior notice!Application Case